Solution for the Pneumatic Caisson Method

Solution for the Pneumatic Caisson Method

What Is the Pneumatic Caisson Method

The term pneumatic caisson method refers to a construction technique in which pneumatic means air, and caisson means a watertight box or cylinder sunk into the ground or water. This method is widely used for bridge and building foundations. It is also applied to infrastructure such as sewage pump stations, underground regulating reservoirs, vertical shafts for shield tunnels, as well as main structural components of subway and road tunnels (e.g., emergency exits and ventilation openings).

In this method, a reinforced concrete caisson (structure) is constructed above ground. A working chamber is provided beneath the caisson, where excavation equipment and earth buckets for soil removal are installed. Excavation, soil removal, and controlled sinking of the caisson are repeated to advance excavation vertically downward.

A key feature of this method is that compressed air, balanced against groundwater pressure, is supplied to the working chamber to prevent groundwater inflow. When the air pressure in the working chamber exceeds a certain level, remote operation becomes the standard practice. Excavation work is carried out by operating a caisson shovel suspended from ceiling rails inside the caisson.

The caisson is supported by reaction forces from the surrounding ground. As excavation reduces these reaction forces, allowing the structure to sink, precise settlement control is essential. One of the most important indicators for settlement management is understanding ground conditions, which has traditionally relied on visual inspections, such as personnel entering the caisson under high-pressure conditions or observations using ceiling-mounted cameras.

Challenges of the Pneumatic Caisson Method

Entering the caisson to assess ground conditions can take several hours depending on depth, and working under high-pressure conditions carries the risk of decompression sickness. In addition, ceiling cameras have a limited field of view, requiring multiple video feeds to be combined, which makes it difficult to gain an overall understanding of the entire site.

If construction proceeds without accurately understanding conditions inside the working chamber, there is a risk of caisson tilting or sudden settlement.

Furthermore, across the civil engineering industry, the working-age population is declining and aging. Due to its nature, the pneumatic caisson method tends to concentrate construction during dry seasons, making it difficult to secure sufficient operators and requiring personnel adjustments across multiple sites.

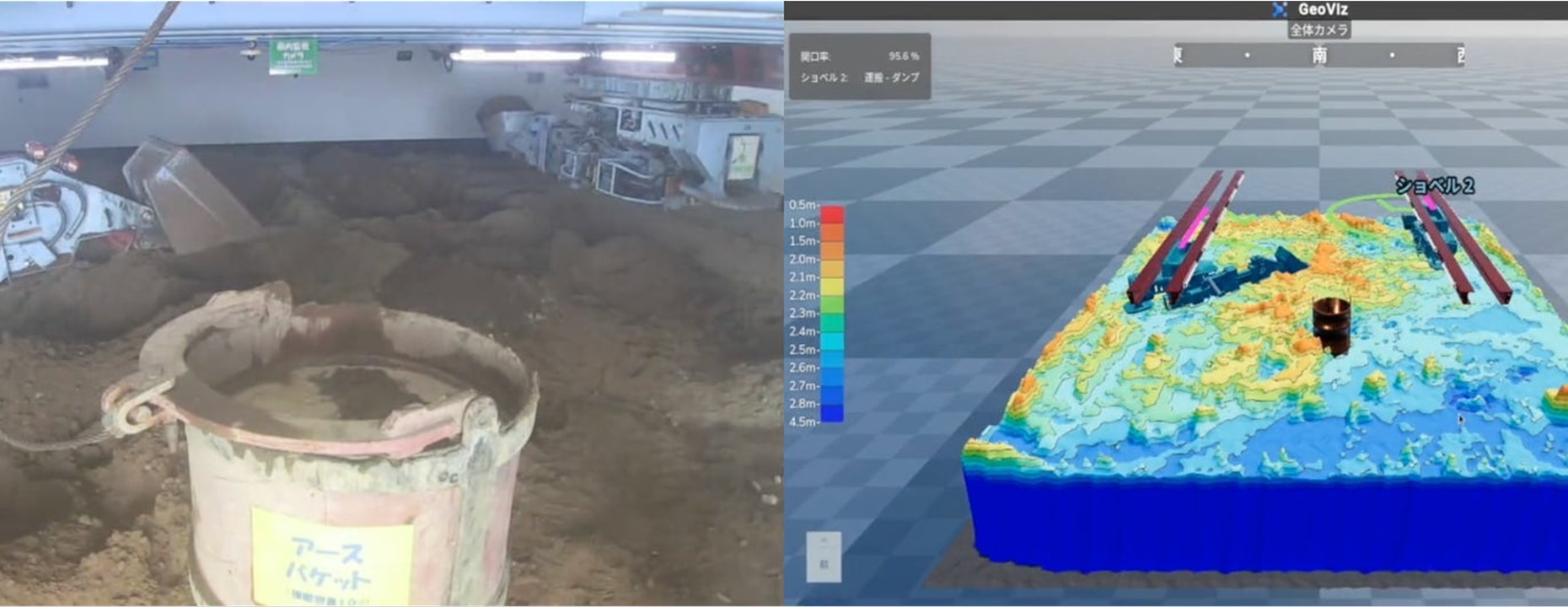

Actual site conditions as seen in camera images used by operators.

Compared with other industries, the construction industry has a higher aging rate, and labor shortages are expected to remain a major challenge both now and in the future. As a result, there is a strong push toward labor-saving and automation initiatives. Autonomous operation of construction machinery is expected to contribute significantly to labor shortage, automation, and improved safety, helping to alleviate these industry-wide challenges.

This initiative aims to address these issues by promoting ICT integration and automation in the pneumatic caisson construction process.

Solution Overview

This solution is an integrated package consisting of the following two systems:

-

1.Visualization System (GeoViz)

- Real-time visualization of ground height, work progress, and opening ratio inside the caisson

- Integration of data from multiple shovels on site, enabling centralized management in a monitoring room

- Accumulation and output of data for use in daily reports and post-construction reviews

-

2.Autonomous Operation System

- Automation of soil transportation tasks using multiple caisson shovels based on user-defined work instructions

- By handling repetitive tasks through autonomous operation, operators can focus on monitoring and higher-difficulty tasks, contributing to labor reduction and shorter working hours

Features of the Visualization System

-

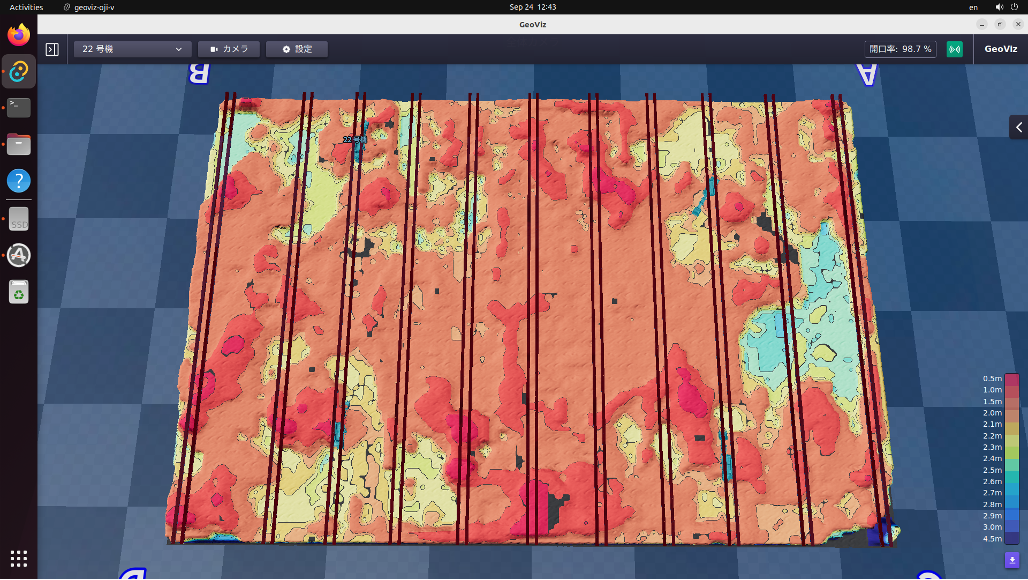

1.Real-Time Display of Ground Conditions and Progress

- By combining point cloud data acquired by LiDAR with information on shovel position and posture, the system provides an intuitive, real-time 3D visualization of ground conditions inside the caisson. This allows site personnel to check construction progress at any time.

-

2.Automatic Calculation and Monitoring of Opening Ratio

- The opening ratio, a critical indicator for settlement management, is automatically calculated and monitored. Exceeding predefined thresholds can be immediately detected.

-

3.Data Accumulation and Report Output

- Changes in ground conditions and trends in opening ratio are stored as data and can be used for creating daily and weekly reports, as well as for construction verification and analysis.

Features of the Autonomous Operation System

- 1.Simple Work Instructions and Automated Excavation Based on Target Ground Shap

- Excavation area: where and how deep to excavate

- Soil disposal area: where excavated soil should be transported and dumped.

- Automatically calculates machine trajectories based on ground geometry

- Operates construction machinery autonomously along the calculated trajectories

- Continuously performs excavation and soil disposal within the specified area until the target depth is reached

Using the system’s GUI—which visualizes ground and machinery status in real time—users specify the following for each shovel:

Once settings are complete, autonomous operation begins with a single press of the “Start Autonomous Operation” button.

After initiation, the system executes tasks in the following sequence:

This enables users to automate the entire process from excavation to soil disposal for a designated area using only simple configuration steps.

- 2.Simultaneous Autonomous Operation of Multiple Machines

- By assigning work areas and starting autonomous operation for each shovel, multiple shovels can operate simultaneously. The system is equipped with functions to detect and prevent collisions between shovels and with walls or equipment in advance, ensuring safe autonomous construction.

- Once work instructions are set, users only need to monitor machine behavior. This allows a single operator to manage multiple machines, delivering significant labor-saving benefits. Continuous autonomous operation during non-working hours (e.g., nighttime) is also possible, contributing to overall schedule reduction.

-

3.Easy Switching Between Remote Control and Autonomous Operation

- The system allows seamless switching between autonomous operation and manual remote control. When autonomous operation starts, the system automatically switches to autonomous mode, and upon task completion, it returns to remote control mode. Even during autonomous operation, users can interrupt the process and switch to remote control instantly with a single button.

Field Demonstrations and Deployment Examples

DeepX has collaborated with Oriental Shiraishi Corporation (hereinafter “Oriental Shiraishi”) to conduct demonstrations of this solution at multiple pneumatic caisson construction sites.

Field Demonstration of the Caisson Shovel Autonomous Operation System

In 2025, a field demonstration of the autonomous operation system was conducted at a site constructed by Oriental Shiraishi. The results confirmed that multiple caisson shovels could perform soil transportation tasks stably over long periods in actual pneumatic caisson construction environments.

On-Site Deployment of the Visualization System (GeoViz)

In 2024, the first demonstration deployment of GeoViz was carried out at a construction site managed by Oriental Shiraishi. By reproducing caisson shovels and ground geometry on a digital twin, the system enabled intuitive visualization of overall ground conditions—something difficult to achieve using remote operation cameras alone.

Reference Articles

Construction Machinery & Construction (April 2025 issue)

ACe Construction Industry (January 2025 issue)

Oriental Shiraishi Corporation

Oriental Shiraishi Corporation engages in a wide variety of social infrastructure construction projects including bridges, highways, railroads, and lifeline facilities. Vast natural landscapes and future-oriented cities are the stages in which they utilize their state-of-the-art engineering capabilities and technologies. The technologies they specialize in include prestressed concrete products, construction, pneumatic caissons, structure retrofits and revamps. Their social infrastructure construction projects enhance people’s lives and ensure high safety standards through a variety of innovative technologies developed with the corporation’s extensive construction experience and R&D efforts. Oriental Shiraishi Corporation is continuously striving to improve the urban environment, develop new infrastructure, repair and reinforce existing infrastructure, and provide disaster countermeasures against natural disasters. Based on their management philosophy, ”Leveraging state-of-the-art engineering capabilities and technologies to contribute to society”, the company will continue to make steady progress.

Please visit this company's websiteContact

If you have any inquiries or would like to discuss your project, feel free to reach out.