株式会社DeepXは、2023年、オリエンタル白石株式会社とともに、ニューマチックケーソン工法で使われる建機「ケーソンショベル」向けに、建機自動運転システムを開発し、実証実験を通してケーソンショベルを複数台同時に自動化でき、かつ、本システムが現場導入に必要な性能を満たしていることを確認しました。

■建設産業における建機自動運転の意義

建設産業では、他産業と比べて、高齢化率が高く、現在から将来にわたり、働き手不足について大きな課題となっています。近年、建設業全体で、働き手不足を解消すべく、省人化や自動化を推進する動きが強くなっています。その中で、建設機械の自動運転は、省人化や自動化、安全性の向上につながり、本業界の大きな課題を緩和・解消しうるとして期待されています。

■ニューマチックケーソン工法

ニューマチックケーソン工法は、橋梁や建造物の基礎として、また、下水ポンプ場、地下調整池、シールドトンネルの立坑、地下鉄や道路トンネルの本体構造物として幅広く活用される工法です。地上で鉄筋コンクリート製の函(躯体)を構築し、躯体下部に作業空間を設け、ケーソンショベルや排土するためのアースバケットを設置し、掘削と排土および躯体の沈下を繰り返すことで、縦に掘り進めます。

■今回開発・実証した建機自動運転システムの特徴

今回開発及び実証したケーソンショベルの自動運転システムは、ケーソンショベルを操作し地山の掘削及び掘削した土の運搬を自動化することができます。本システムの主な特徴を5つ紹介します。

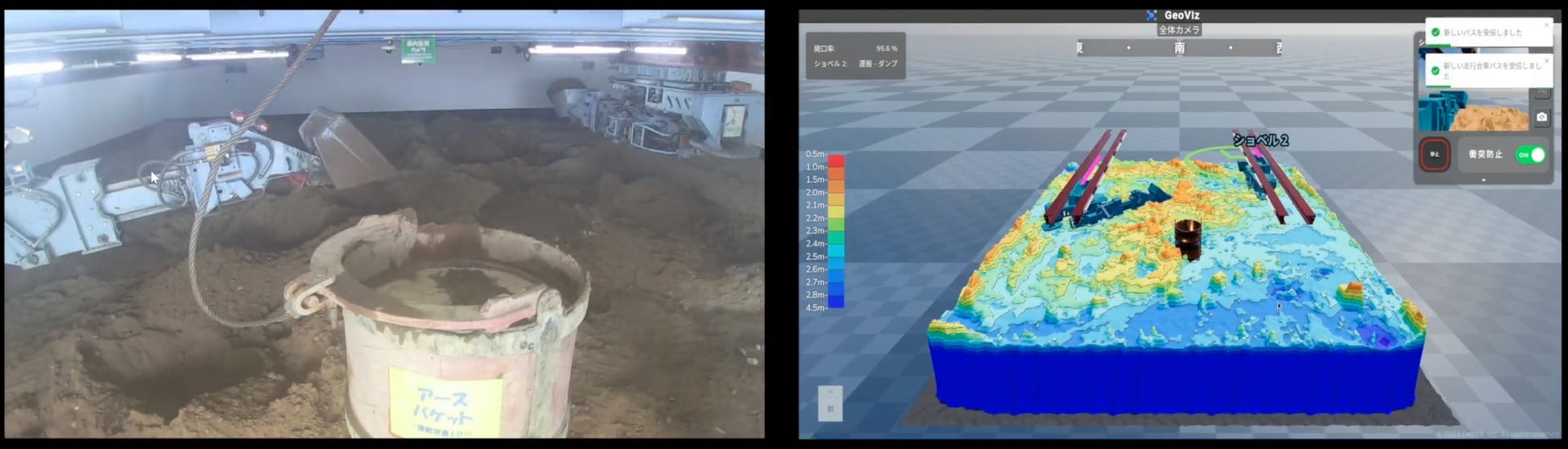

・リアルタイムなデジタルツイン可視化

本システムは、デジタルツイン形式でリアルタイムに、2つのケーソンショベルの位置と姿勢、および、地山の形状、高さを認識し、3次元に可視化できます。特に、ニューマチックケーソン工法に特徴的かつ重要な作業状況を示す指標である開口率も自動で計算できます。これにより現場作業者や監督者は現況をいつでもすぐに俯瞰的に確認でき、作業効率や管理効率が向上します。

・衝突防止

本システムには、ケーソンショベル同士の衝突を防止する機能があります。具体的には、2つのケーソンショベルが一定以上近づくと画面上にアラートを発し、また、さらに一定以上近づくと画面上に警告を発した上で動作が停止します。これによって、複数の建機の自動運転時だけでなく、自動運転と手動運転が混在する場合でも建機同士の衝突を防止することができ、作業全体の効率や安全性が向上します。

・作業内容を指定しやすいUI

ユーザは、リアルタイムに地山や建機を可視化する本システムのGUI上で、各ショベルごとに掘削エリア(どの土を掘るか)及び排土エリア(掘った土をどこに運ぶか)を指定し、自動運転開始ボタンをクリックするするだけで自動運転ができます。自動運転開始後、本システムが 1) 機械を動かす軌道を地山の形状などを考慮し自動で算出し、2) 算出された軌道に従って建機が自動に動き、3) 一連の動作として指定された領域で掘削及び排土を自動で連続して行うことができるようになっています。

・複数台同時自動操作

ユーザは自動運転開始後は、基本的には、建機の挙動の監視だけを行えば良いため、複数台の建機を1人で動かすこともでき、省人化効果を期待されています。また、普段作業が行われない時間帯(例えば、夜間等)に連続して自動運転をさせることもとでき、それによって、工期全体を短くできる可能性も期待されています。

・安定的な自動運転と自動運転が有効な条件外におけるシームレスな手動操作

本システムは、リアルタイムな周辺環境認識の仕組みだけでなく、地山の形状や硬さを考慮した掘削操作が可能です。そのため、一定の範囲で環境の変化に対してロバストなシステムとなっており、条件のバリエーションやばらつきの多い建設現場においても安定的な自動運転が可能となっています。上記で対応できないイレギュラーな状況に遭遇した場合、手動操作に切り替え、人手によって状況を改善した上で、自動運転に切り替える運用を想定しています。本システムは、そうした運用に対応するために、簡単に自動運転から手動操作に、また、その逆に手動操作から自動運転に切り替えることができます。

また、今回開発した建機自動運転システムのユーザであるオリエンタル白石の技術本部の根岸氏からは「システムの画面が見やすく、直感的かつ簡単な操作で自動運転を実行できます。1人のオペレータでも、複数の建機を同時に自動で止まることなく動かし続けることができ、非常に便利です。今後は、現場への導入を推進すると同時に対応できる作業範囲を広げたり、より多くの建機を同時に動かしたりすることにチャレンジしていきたい」とご評価いただいております。

■今後の展開

今回開発した建機自動運転システムを今年度中に現場に導入し実運用を開始する予定です。今後も引き続き建機自動運転の実用化に向けたフロンティアを開拓していきたく考えています。

■オリエンタル白石株式会社について

オリエンタル白石は、プレストレストコンクリートやニューマチックケーソン工法、補修補強技術など数々の特化技術を 活かし、大いなる自然と大地・未来を見つめる都市を舞台に、橋梁や高速道路、鉄道、ライフライン施設など多種多様な 社会資本を構築しています。人々の暮らしに潤いをもたらし、安全を約束する社会資本の建設には、当社の施工実績と研 究開発によって培われブラッシュアップされた技術の数々が活用されています。これからも、都市環境の整備や新たなイ ンフラ構築の他、既存のインフラの補修・補強、巨大地震やゲリラ豪雨などへの災害対策にも尽力し、「人と技術を活かし、常に社会から必要とされる集団を目指す」という経営理念のもと、着実な発展を続けて参ります。