建機の自動化技術を開発するDeepXは、現場の地上計測室や現場外からいつでもリアルタイムに、現場の地下作業区画をデジタルツインにより確認できる施工管理システムを開発し、ニューマチックケーソン工法の国内シェアNo1のオリエンタル白石に提供を開始しました。

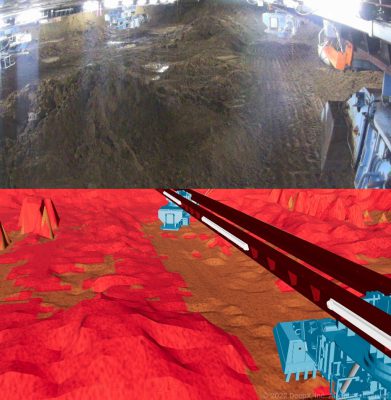

(上)建設現場の様子 (下)デジタルツインシステム

現場における課題

ニューマチックケーソン工法は、作業室が高気圧な地下空間であり、身体への負担が大きい環境です。そのため、入室後に長時間減圧室に入る必要があり、かつ、限られた時間しか作業室にいられず、入室することの時間的/身体的コストが高いことが課題でした。

近年ではオペレータはほぼ遠隔操作で作業しているものの、遠隔操作用のカメラだけでは、

・現場監督者が作業室内の全体状況を正確に把握できない

・オペレータが地面までの距離感を掴めず、作業効率が低下する

といった課題があります。1日の終わりに作業員が作業室に入り、直接測量することが現場では未だに求められております。

最先端デジタルツイン技術により高度な施工管理を実現

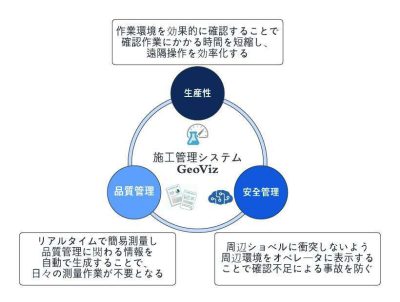

DeepXは、建機自動化システム開発で培った認識技術を活用し、作業室内の全体状況をリアルタイムかつ正確に測量/可視化するシステムを実現し、現場の時間的/身体的コストを大きく低減しました。

遠隔操作室から作業室の測量結果が常に確認できるため、現場監督者は毎日作業室に入る作業が不要になります。オペレータは建機と地面との位置関係を俯瞰的に確認でき作業効率が向上します。また、現場監督者のレポート作成にかかる時間短縮や、施工関係者とのコミュニケーションミスの防止などの効果も期待できます。

ニューマチックケーソン工法の完全自動化に向けて

建設業界は深刻な人手不足に見舞われており、生産性の改善や現場作業員の省人化が急務です。

今後は、DeepXの建機自動化技術をニューマチックケーソン工法に展開し、ケーソンショベル作業の自動化による現場の生産性向上と省人化を目指してまいります。

■株式会社DeepXについて

DeepXは、「あらゆる機械を自動化し、世界の生産現場を革新する」というミッションを掲げて活動する、東京大学松尾研究室発のAIスタートアップです。多くの産業で問題となる労働力不足、熟練作業者不足、過酷作業等の現場の課題の解決を目指し、AIをはじめとするさまざまな技術を駆使し、あらゆる機械を自動化し、幅広い作業の自動化を推進してまいります。

本社所在地 東京都文京区湯島三丁目21番4号第一三倉ビル3階

設立 2016年4月22日

代表者 代表取締役 那須野薫

事業内容 機械自動化や現場作業自動化の支援、AI技術を活用した事業開発、ソフトウェア開発、R&D

URL https://www.deepx.co.jp/

■オリエンタル白石株式会社について

オリエンタル白石は、プレストレストコンクリートやニューマチックケーソン工法、補修補強技術など数々の特化技術を 活かし、大いなる自然と大地・未来を見つめる都市を舞台に、橋梁や高速道路、鉄道、ライフライン施設など多種多様な 社会資本を構築しています。人々の暮らしに潤いをもたらし、安全を約束する社会資本の建設には、当社の施工実績と研 究開発によって培われブラッシュアップされた技術の数々が活用されています。これからも、都市環境の整備や新たなイ ンフラ構築の他、既存のインフラの補修・補強、巨大地震やゲリラ豪雨などへの災害対策にも尽力し、「人と技術を活かし、常に社会から必要とされる集団を目指す」という経営理念のもと、着実な発展を続けて参ります。

■お問い合わせ先

info@deepx.co.jp

※世界初

自社調べ。ニューマチックケーソン工法における現場運用可能なデジタルツイン施工管理システムについて2022年10月にインターネットで調査を行った結果、世界的に類似のソリューションが無いため、世界初と表記しています。